3D PRINTING

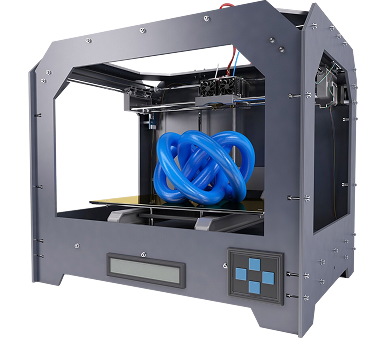

3D printing is an advanced industrial process that constructs three-dimensional objects layer by layer directly from digital CAD models using materials such as polymers, metals, or composites.

Technical Specs

All the Specifications You Want

Multi-Color Printing

Experience dual-extrusion and AMS-based printing with multiple filaments, perfect for detailed, colorful models or multi-material functional prototypes in one go.

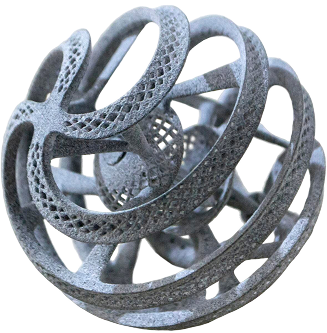

Ultra-Fine Print Quality

Get incredibly detailed results with up to 22μm resolution and 8K resin output—ideal for miniatures, dental models, and intricate artistic pieces.

Precision Grade Prints

Ensure accuracy up to ±0.05mm using Voron and Prusa printers, delivering consistent, reliable parts for prototyping, tooling, and mechanical assemblies.

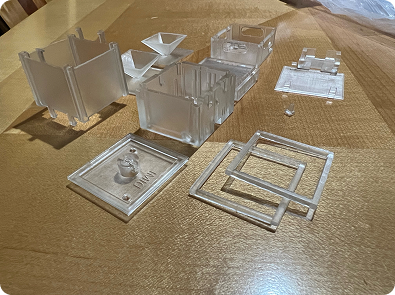

Wide Material Compatibility

We support materials like PLA, ABS, PETG, TPU, Nylon, and resins—offering tailored properties for flexibility, toughness, transparency, or fine finish.

High-Speed Printing

Print at speeds up to 500mm/s using Bambu Lab and Voron systems, cutting lead times while maintaining top-tier surface finish and strength.

Technology Support

Choose from SLA, LCD resin, and FDM printing, depending on your design complexity, resolution needs, and durability requirements for optimal output.

Printers Powering Burk’s 3D Printing Farm

Types of 3D Printers

Printers can be broadly categorized into the following types based on technology and functionality:

FDM Printers | SLA Printers

PRUSA XL

An FDM printer that is large-format, modular, and capable of multi-material high-precision

printing.

PRUSA MARK 3/ MARK 4

An FDM printer that is reliable, user-friendly, and equipped with advanced performance features.

BAMBU LAB X1 CARBON

An FDM printer that is high-performance, fast, and supports carbon fiber filament with advanced automation.

PHROZEN MIGHTY 4K

An SLA printer that is designed for professionals needing high-resolution prints and larger build volume.

VORON V2

An FDM printer that is open-source, customizable,

and built for high-speed, high-precision

printing.

PHROZEN MEGA 8K

An SLA printer that is ultra-precise, fast, and ideal for producing highly detailed large-scale resin prints.

Enhancing Your Prints

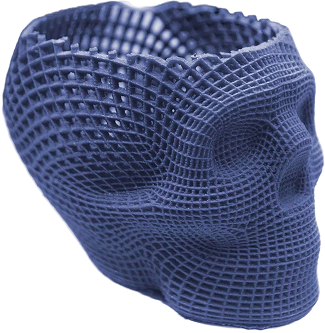

3D Printed Models

Leverage cutting-edge 3D printing technology to enhance manufacturing with our expert services

The Printing Services

Post Printing Services

- Surface Finishing and Smoothing

- Painting and Coating Application

- Dimensional Accuracy & Assembly Testing

Upload. Submit. Get Your 3D Print Delivered!

If you have any questions or require assistance, please do not hesitate to contact our team.

We will be delighted to assist you.